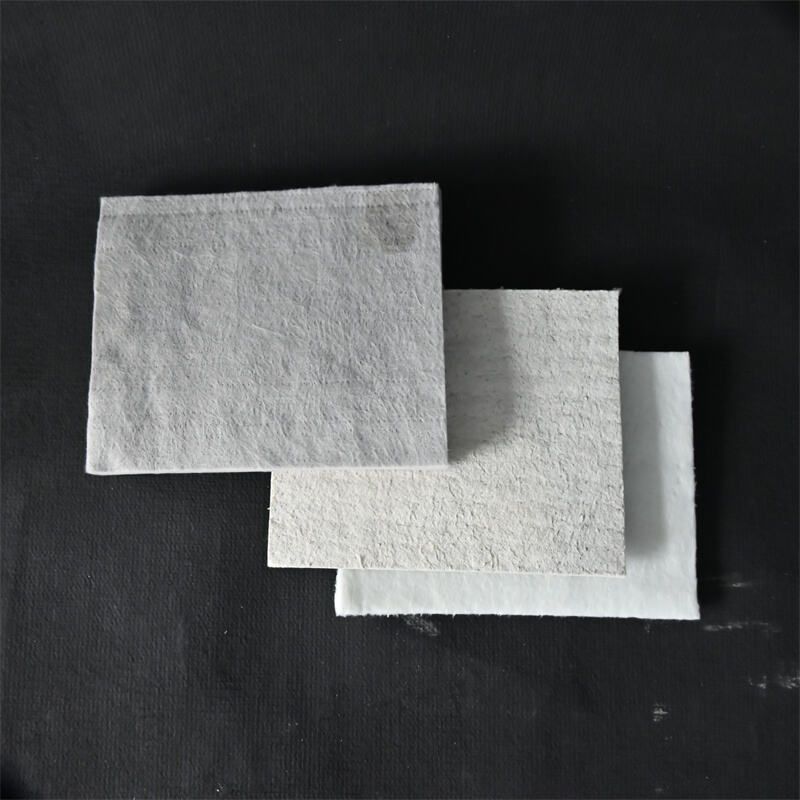

Description

Aerogel material has excellent heat insulation performance, but it cannot be directly used in the battery industry due to the large amount of surface dust. At present, the aerogel thermal insulation pads on the market are mainly the first and second generation products. The first generation products mainly use Pl or PET film to encapsulate aerogel heat insulation sheets, which is complicated in the production process, and has the disadvantages of high cost, high density, large space occupation, and the coating film is not resistant to high temperature.

The second generation product is to use flame retardant coating to coat the surface of aerogel. If the coating is too thin and the package is not tight, there will still be dust escaping. If the coating is too much, the heat insulation performance will be lost and the density will increase more.

The third generation aerogel heat insulation pad exclusively developed by Shengrun New Materials Co.,Ltd. can achieve dust-free body on the premise of ensuring excellent heat insulation performance at high temperature, and the total cost is significantly lower than that of the previous two generations, which is very suitable for the current development of new energy vehicles for the need of new heat insulation patches with high cost performance.